|

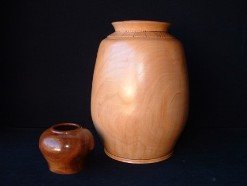

Hollowing - Let's make the chips fly!Hollowing, in the woodturning world is how one removes the material from the inside of urns, vases, closed forms, etc. Because of the depth or sharp angles of these items, a normal gouge or scraper, should not be attempted for safety reasons. There are several different hollowing systems available today. The first one that I purchased was a Robert Sorby arm brace set up. The items pictured here were made using the arm brace.  The one on the left is a spalted maple closed form measuring 6” diameter x 1-5/8” height using our 6” x 2” bowl blank.

The item below is much larger measuring 17-1/2” diameter x 8-1/2” height. It is a spalted wormy pecan urn with a walnut foot and top piece. Yes, the worm holes made it an extra challenge because of the risk of getting a catch which could easily have destroyed the piece. Since this was such a large item chip build up was a problem as I was working through a 2-3/8” hole at the top. The worm holes actually allowed some chips to fly out which was an advantage. This finished item is a good example of a less than perfect woodturning blank. Some turners may have thrown it out as an unusable turning blank. I chose to challenge myself by turning it into a one of a kind piece of art. I have displayed this piece at home shows and galleries. When I have this item on display at art shows, it always draws people into our booth and generates positive comments by art collectors and questions by fellow wood turners. Many are surprised that I made this using only one gouge and an arm brace tool. These are examples of urns made using the arm brace: I soon wanted to make urns and vases that were sixteen or eighteen inches in depth, so I needed a deep hollowing system. I used the first deep hollowing system that I purchased the way that it came for two or three times before I started to modify it. The biggest drawback to this system was that the cutter is mounted on an arm which is fixed in the straight out position. The only adjustment on this tool was the ability to rotate the cutter itself. Even after making some attachments of my own, which allowed me to use other system’s cutters; I was still limited by the size hole that I was working through and the diameter of the item. I wanted to keep the opening size as small as possible to allow more wood grain to be shown on the top of the item. Another problem was determining wall thickness. I soon realized that other than by sound and using my hand, if it would fit inside the item, there was no way to check the wall thickness when over reachable depth by calipers. I had seen a picture of an adjustable arm with a laser light that clamped on the bar itself. After purchasing some ½” square tubing, doing a little cutting and welding and making a trip to the hardware store for knobs and bolts and to the local office supply store for a laser pointer I made my own laser light measuring system for about $25.00. I still use that self modified system for turning items like the black olive urn shown above. But because of its fixed straight arm I was not able to reach inside at as sharp an angle as I would have liked when making some closed forms. After doing my research and trying alternate systems, I settled on what is now system number three. I chose the Oneway hollowing system.

|

This system works by setting the wall thickness measurement that you would like between the light beam and the cutter itself. When beginning, the laser light shows as a dot on the top side of the item; as you approach your finished wall thickness the light slides down the side and becomes elongated, which can be seen in the picture below.

This system works by setting the wall thickness measurement that you would like between the light beam and the cutter itself. When beginning, the laser light shows as a dot on the top side of the item; as you approach your finished wall thickness the light slides down the side and becomes elongated, which can be seen in the picture below. This system comes with four interchangeable cutter arms from straight to what is called a double bend. There is also an adapter available which allows you to use the arms and cutters from other brand’s systems. It also comes with its own adjustable laser light arm. The arm can easily be installed or removed as needed. I am very satisfied with this system. I have been using it for a few years now.

This system comes with four interchangeable cutter arms from straight to what is called a double bend. There is also an adapter available which allows you to use the arms and cutters from other brand’s systems. It also comes with its own adjustable laser light arm. The arm can easily be installed or removed as needed. I am very satisfied with this system. I have been using it for a few years now.